vcb bottle testing|vacuum bottle breaker testing : solution Field Testing of Vacuum Circuit Breakers. Vacuum circuit breaker uses vacuum as arc quenching medium inside a vacuum bottle. Vacuum circuit breakers are a dependable current interruption . Terms - OlympiaTV

{plog:ftitle_list}

WEBO "sobrenome" da Caixa Econômica. Aqui estão todas as respostas de O "sobrenome" da Caixa Econômica. Esta pergunta faz parte do popular jogo CodyCross! Este jogo foi desenvolvido pela Fanatee Games, uma empresa de videogames muito famosa. Como você já está aqui, é provável que esteja preso em um nível específico e esteja .

There are vendors that offer DC output vacuum bottle testers that offer a go/no-go test with good or bad indictor lights. Not only are these DC devices, but they are single application devices .Field Testing of Vacuum Circuit Breakers. Vacuum circuit breaker uses vacuum as arc quenching medium inside a vacuum bottle. Vacuum circuit breakers are a dependable current interruption .

When vacuum interrupters are manufactured or used in field there are three tests used to validate their function :1: contact resistance, 2:high potential withstand, 3:The leak .

unique problems encountered analyzing forensic evidence vs laboratory standards

Testing with dc voltage is quite popular in the field because the test units are considerably smaller than an ac test set, but only the ac set provides the frequency necessary to evaluate capacitive coupling of the equipment components. The vacuum integrity test set is considerably smaller than a normal power frequency withstand test set. In this video, I have shown how to do a contact resistance test for a 15kv vacuum circuit breaker.Testing Phase Sequence / Feeder Line to Line Voltage Checki.In the international standards for medium (and high-) voltage circuit-breakers no distinction is made in test requirements between circuit breakers with different arc-quenching media, like SF/sub 6/, oil and vacuum. This has led to the necessity to formulate a few additional test-requirements and interpretations that are specific to vacuum circuit breakers (VCB) only. In . Factory testing can utilize either AC or DC high-potential test sets, and various portable test sets from manufacturers are accessible for conducting high-potential tests on open vacuum interrupters. . Additionally, it aims to evaluate the integrity of the vacuum bottle, measure leakage current, and assess insulation between the circuit .

withstand test be performed prior to initially putting this or any type vacuum circuit breaker into service. Refer to "Dielectric Tests" in the "Adjustments, Tests and Periodic Maintenance" section for the correct test procedure. Manual Operation For Inspection The electrically operated circuit breakers can be charged manually with a removable .

vacuum bottle test voltage

Is the vacuum bottle test tytpically done as a factory test, or field acceptance test? One of the specification requirement mentions the field tests (including . Yes, vacuum bottle is a required NETA acceptance test on VCB's. When you call someone to get that transformer tested, do the VCB;s too. Be sure to follow precautions for exposure to . Key learnings: Vacuum Circuit Breaker Definition: A vacuum circuit breaker is defined as a type of circuit breaker where arc quenching occurs in a vacuum, mainly used for medium voltage applications.; Vacuum Interrupter Structure: The vacuum interrupter, essential for VCB operation, consists of a steel arc chamber and ceramic insulators with a vacuum .

Short Circuit Test: The VCB is subjected to short-circuit currents to assess its ability to interrupt high fault currents. Vacuum Contactor Unit. Apart from being used as circuit breakers, Vacuum interrupters are also employed in Vacuum Contactor Units (VCUs). VCUs are designed for switching and controlling high current loads, such as motors . The circuit breaker can be closed only in ‘TEST’ and in ‘SERVICE’ position. VCB of lower rating cannot be inserted in to the panel of VCB of higher rating. VCB cannot be put in to service unless the multiple plug is in position. The door can only be opened when breaker is in ‘OFF’ position or vice a versa.

️ ️https://bit.ly/31ZCREX ️ ️The Channel Sok Sophea EDC official, this is best Channel.

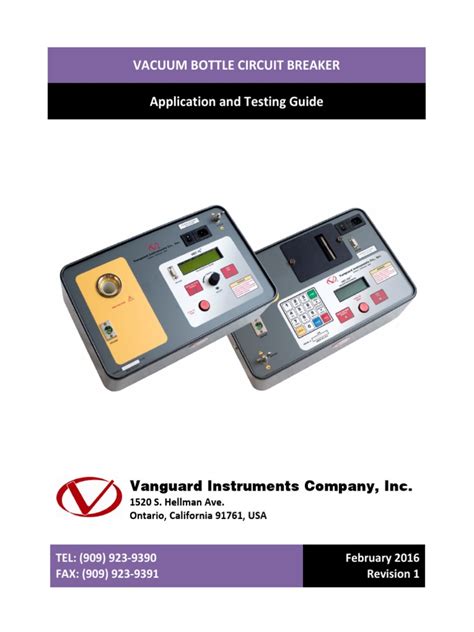

The VBT-75 S2 is Vanguard's second generation microprocessor-based, portable, 75kV dc vacuum bottle tester. This lightweight, portable tester is designed for testing circuitbreaker vacuum bottles in the field and at the shop. Test voltages can be selected from 10 kV dc to 75 kV dc in 5 kV steps. The high-voltage test time can be set from 5 .Get the BEST PRICE at IndiaMARTVacuum Interrupters: https://dir.indiamart.com/impcat/vacuum-interrupters.html?utm_source=226&utm_medium=YT7&utm_campaign=YTIV.

The first step in VCB testing is to conduct insulation resistance tests to verify the integrity of insulation materials within the circuit breaker. This test helps in identifying any potential insulation breakdown or contamination that could lead to malfunctions. . Our Vacuum Bottle Test Results Revealed. Next: Learning from the Unexpected .

A breaker which used vacuum as an arc extinction medium is known as a vacuum circuit breaker. Discover our range of products in Indoor Vacuum Circuit Breakers: EasyPact EXE, Evolis, HVX, LF, SF, VA.Testing For most of us charged with maintenance of systems that use vacuum technology, the design of the bottle is of little concern until it is time to test or replace one. At that time, understanding vacuum interrupter technology becomes more important. ANSI/IEEE C37.60 for production test-ing and C37.61 for maintenance testing are two sources. @Engineering-in-tamil #VCB #Breaker Vacuum Integrity TestsThe purpose of a vacuum integrity test is to confirm that the pressure in a vacuum interrupter is l.

The test is carried out in a fully automatic test cabin with the travels adjusted to the respective type. Bellows lifetime are over 30,000 CO operation cycles. Operation . Tens (or hundreds) of bottles are processed in one batch, using a high-vacuum furnace that heats them at temperatures up to 900 °C and a pressure of 10 −6 mbar. [6]To test VCB Bottles we have developed a specialized Vacuum Bottle test Set. This is a portable microprocessor based equipment with in built 60KVDC source and controllers to test bottles at high voltage. The vacuum bottles can be tested just by drawing out the breakers (without even removing the bottle) in less than 5 minutes time. Specifications :

used medical laboratory analyzers

#electricalinterviewquestions #electrical #circuitbreaker #vcb AFTER WATCHING THIS VIDEO YOU WILL CLEARLY UNDERSTAND WHAT IS INSIDE THE VACUUM BOTTLE OF VCB.Effective 03/2013 Supersedes I.B. 32-255-1H dated December 2006 3A74374H04 (I.B. 32-255-1J)A suitable test voltage (DC) is applied to the breaker and the result is known immediately. You can select test voltages from 10 to 60 kV DC and one of these voltages can be customised to your specifications when ordering. Reading the unit is also easy: if the interrupter is approved, a green light is shown, if it is defective, a red light is . Like alloys, copper-bismuth or copper-chrome is an excellent material for making VCB contacts. . Testing of a circuit breaker, in general, is mainly used to test the operation of both separate switching mechanisms as well as the timing of the overall tripping system. Once vacuum interrupters are designed or used in the field.

Alloys like, Copper-bismuth or copper-chrome is the ideal material to make VCB contacts. Vacuum Circuit Breaker Construction. . Generally, circuit breaker testing is mainly used to test both the separate switching mechanisms’ performance as well as the overall tripping system’s timing. Once vacuum interrupters are designed otherwise . Group CBS Chief Scientist Finley Ledbetter presents detailed information on vacuum interrupters manufacturing, function, testing, and modes of failure.

vacuum bottle breaker testing

vacuum bottle breaker test voltage

This vdo about live demo of VCB Maintenance & Testing //ABB //VD4 //Vacuum //Megger Test //CRM Test & //Timing Test सरल भाषा हिंदी में समझना .More videos we'.For testing personnel, the design of the bottle is of little concern until it is time to test or replace one. At that time, understanding vacuum interrupter technology becomes more important. Two reference sources are ANSI/IEEE C37.60 for production testing and C37.61 for .Vacuum Bottle Insulation Integrity Test - HighTest Technology - Transformer Test Equipment ~ Circuit Breaker Timer, Winding Resistance, Transformer Ratio

using science skills analyzing a laboratory investigation

vacuum bottle breaker maintenance test

WEBNo final deste vídeo eu mostro como o saldo final de mais de R$30 MIL feito com o aplicativo de sinais. Todos os usuários já estão recebendo acesso a esta nova .

vcb bottle testing|vacuum bottle breaker testing